|

Patch Cord Production Equipment

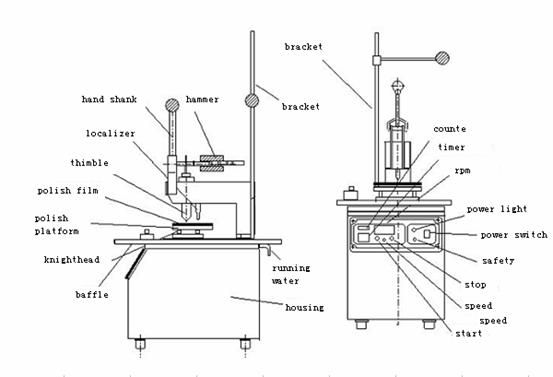

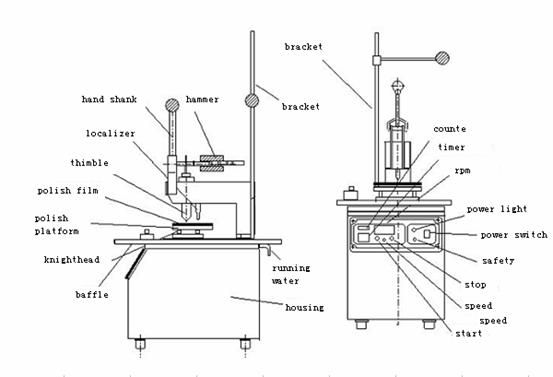

Fiber optic polish machine Fiberer-106

1.1.Working and Running surrounding:

1.2.1 Running surroundings

Temperature: 10° C~40° C

Relative Humidity: 15%~85%

Sound: Vacancy load=50dB

Vibration:

A) Running Status: 0.25g 5~100Hz 10min

B) Stop Status: 0.50g 5~100Hz 10min

Power : 220~230VAC 50Hz/60Hz

Voltage: 110W

Running speed: 20~220RPM

1.2.2 Running surrounding:

Surrunding Temperature:-40° C~85° C

Relative Humidity:15%~85%

Vibration:1.0g 5~100Hz 45min

Acceptable impact:Fall from 50mm high

1.3Application Scope

Fiberer -106 Optical fiber grinder

| Iterm |

Grinded

material |

Specification |

Remarks |

| 1 |

ZrO2

China mandril |

ø2.5mm,ø2.0mmø1.25mm |

Can

be used for PC¡¢APC assembly

or unassembly |

| 2 |

Quartz

capillary |

ø1.8mm |

Can be used for plan, bevel and sphere etc. |

| 3 |

Glass |

ø1.0mm~ø10.0mm |

| 4 |

Stainless steel¡¢Titanium alloy |

ø3.0mm~ø2.5mm |

| 5 |

Colophony |

MT-RJ,MPO and MPT etc. |

Remark:Can

grind 6~12 connectors or mandrils by using

the responding grinding heads.

2¡Main description of equipment name, brand and maintenance.

Table II Parts Name Type/specification?Orientation

Original,Life period and maintenance etc.

|

Iterm |

Description |

Type/specification |

| 1 |

Power switch |

Controlling the power supply to be on / off |

| 2 |

FUSE |

Specification£º250V/3A |

| 3 |

Timing potentiometer |

Adjusting the speed of motor to grind the diferent

materials. |

| 4 |

Grinding plate |

Having the grinding film and the grinding slice are put on it. Making the

grinding slice

Grind the base surface of mandril to be the proper shape and roughness by the grinder¡¯s

running mechanism. |

| 5 |

Fiber shelf |

On the process

of grinding£¬can

hang the cricoid the end fiber.Can

adjust the height of fiber shelf to avoid the end fiber touch

running mechanism. |

| 6 |

Release button |

Press the start

button then begin to run the equipment and press the stop button

to stop the running. |

| 7 |

Time relay |

Intercalate and

display the grinding time and the MAX value is 99H99M. |

| 8 |

Counter |

Record the grinding time and press reset can count again. |

| 9 |

Hammer |

Adjust the hammer¡¯s

position can adjust the press power and total 4 positions can

be used. |

| 10 |

Pressure Thimble |

Be pressed in the center of grinding jig to provide a

certain pressure. |

| 11 |

Jig clip pin |

Insert in the trough of jig to avoid the rotation of grinding plate¡£ |

| 12 |

Fixing shelf |

|

| 13 |

Grinding plate deposited loo |

|

| 14 |

Motor |

|

Insertion loss& ruturn loss test MC

| SPEC |

|

|

|

|

|

|

|

|

TYPE |

Fiberer -T206 |

|

|

wavelengh |

1310/1550nm |

|

|

range |

0

~ 75 dB |

|

|

WL-calibrate |

1310/1550nm |

|

|

precision |

0.25dB |

|

|

Output stability |

0.05dB/hour

( @ 25° C) |

|

|

Optic

insertion loss |

|

|

WL-calibrate |

850/1300/1310/1550nm |

|

|

range |

(+3

~ -80 dBm) |

|

|

precision |

0.25dB |

|

|

Vision resolving power |

logarithm:0.001dB;linearity:0.001nw/µW/mW |

| |

Test mode |

Linetype&nonlinear |

| |

Plug stype |

FC/SC/ST/LC

adapter etc. |

| |

index |

| |

power |

AC 90-260V |

| |

Operation temperature |

(-5° C ~ +55°

C) |

| |

Guise size |

260×265×140mm |

|

|

weight |

3kg |

|

|

|

|

|

|

|

|

Fiberer

-surface check instrumentation

Features:

1 Use for inspect the surface quality of pins. Apply for all china

pin inspection. Ø2.5mm& Ø1.25mm

2 Can choose the amplificatory multiple of 200X or 400X

3 Easy opera-tion and control by only 1 button.

4 Inner Lamper house is blue and it can make the inspection result

clear.

Outer Red LED lamper house can inspect the tansmission of fiber.

Fiberer CURING

OVEN FOR FIBER OPTIC

1 Heating for almost kind of fiber optic ,such as

FC?SC?LC?MU?MT?ST etc.

2 Two independence control system , 48 ferrules can be heated at the

same time at most.

3 High productivity.

4 Heat even to exhaust the least.

5 Precise control system , adjustable temperature 60~150? , fluctuation

±1? only.

6 Control the heating time by designation.

7 Easy to use and dependable.

Fiberer air-operated press

bonding machine

Features

1 Use for bonding and assembling the china pins of connector and trail

seat and so on.

2 Air pressure can’t less than 0.4~0.6p, The most pressure

is 200kgf.

3 Can assemble and bond various components by change the bonding tools.

4 Can adjust pressure and can be used for all kinds of productions.

5 Foot controlling switch operation. Easy ,reliable and high efficient.

6 Stable process quality

7 Easy and convenient maintenance.

8 Can provide connector bonding molds, adapters and metal trail seat

bonding molds.

9 Can make the responding press bonding tools according to customers’

requirements.

|